On the morning of Tuesday July 28th, we listened in on an Angaza solar lantern training session. Angaza representatives described the details of the operation of the solar lanterns and the online payment system made possible through a sales agent’s smart phone. The system has a lot of potential when it comes to flexibility, monitoring sales, and scalability. But there still is one major issue left: getting the program to download on the business-issued smart phones. Getting the smart phones involved one set of hurdles. Getting the software up and running on the smart phones is still a pressing issue.

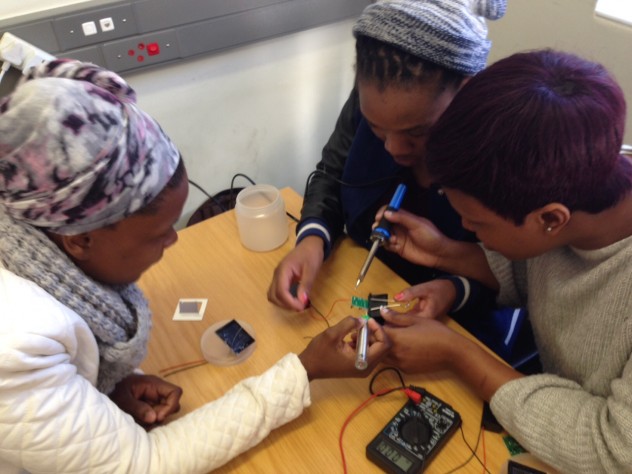

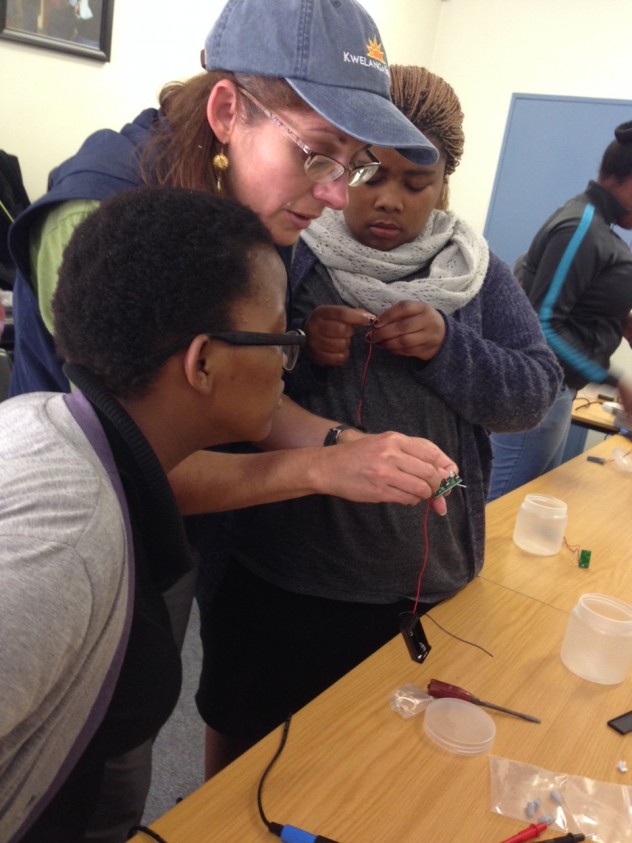

In the afternoon, had our second chance to conduct a solar lantern workshop. This time our audience was the Isibindi Youth in Grabouw. Sindisiwe (Cindy) met us there, and helped us set up the workshop. At first, we thought that we were more prepared with materials; we replenished our silicone sealant and electrical tape, and Natalie helped me to mentally run through all aspects of the presentation (including using a 220V to 120V converter so I don’t blow another fuse!). All materials were carefully spread throughout the room, and power cords, power strips, and adapters were in place. While we were setting up, there was an audience of about a dozen people. As I was starting the presentation (as Natalie warned me previously), more and more came through the door. We kept on trying to find enough seats and enough materials for everyone. And the rest was just a blur 🙂

This time, I realized the greater degree of uncertainties when working with a larger group. At first, we were trying to put the lantern together in a step by step basis. But typically youth work at different speeds, mistakes are made, and others just need help getting the confidence to start. The largest issue were the youth who worked ahead, not really knowing what was to do next. Some students soldered on the solar panel without leading the wires through the lid of the jar. Others soldered in the LEDs backwards. Others didn’t have good connections, and some had low battery power. With the solar jars, it is easier to proactively tell them the right and wrong way to build them instead of going back and trying to fix their mistakes. This time, we had about 8 ‘botched’ jar lanterns. Each of them take about 10 minutes to fix, and that seriously ran us overtime.

The lessons that we learned from this trip are: 1) We need to make up step by step picture cards showing youth how to make the lanterns to overcome the language barrier, 2) We need to cut out more of the ‘beginning’ part of the presentation (about how this project came to be), and 3) we need to consider possibly setting up an ‘assembly line’ method of doing the solar jars. The third idea would involve having students moving from one table to another, only after completing a specific task. The only downfall of this is that it would require 4 or 5 trained staff total, which is a luxury which may not be available.

This is what happens when I get too busy during a workshop and the youth ‘take over’ my camera 🙂

Ed, Natalie, Mark, and I debriefed the day during our last outing together at a wonderful seafood restaurant called the Codfather. I had octopus and calamari, and others shared their sushi with me. The one thing that I will truly miss will be the fresh seafood here. It’s marvelous.